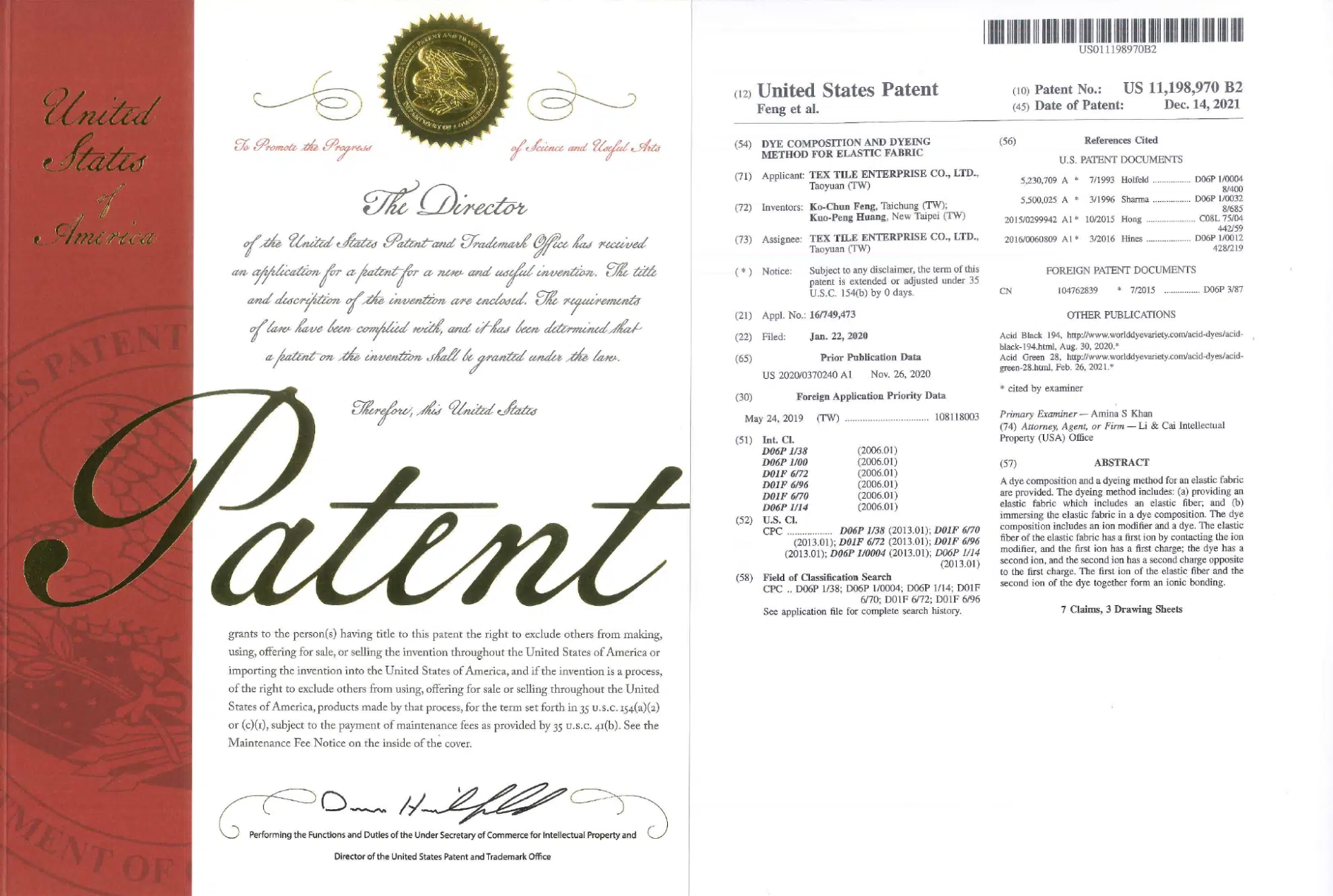

Breakthrough Patents, Global Certifications

Advancing R&D, Achieving Excellence

Backed by 30 years of solid experience and expertise, Tex Tile is committed to pushing the boundaries of textile innovation. With multiple patents and international certifications, we strive for excellence in technology, product quality, and sustainability. We apply the spirit of continuous improvement to our core strengths, as part of our long-term focus on textile advancement.

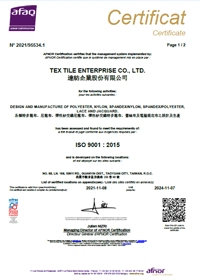

Certified by Internationally Recognized Standards

Tex Tile upholds strict standards to ensure product quality, workplace safety, and environmental protection. This reflects our commitment to self-monitoring and to meeting the expectations of our customers.

Smart Quality Control & Data-Driven R&D

Digitalization enables high-precision, high-standard production.

By integrating standardized SOP processes and IoT-enabled equipment into ERP system, Tex Tile ensures full visibility and control from raw material sourcing and dye formulation to production tracking and final shipment. This connected system allows for precise progress management and efficient output in both quality and volume — delivering high-value textile solutions to meet customer needs.

Track and control key values to ensure accuracy and efficiency.

Core Competence

Tex Tile's ERP system rigorously monitors every parameter throughout the production process. The data collected is applied directly to our quality management policies, helping us maintain and continuously improve high standards of consistency and performance.

Through this data-driven approach, we have successfully developed dyeing technology for ultra-fine polyester fibers, including 75D/144F microfibers. We can ensure color fastness for specific black reaches Grade 4 under both AATCC 61-2A and ISO 105 C06 B2S standards.

Integrated ERP System

Standardized Processes

Stable and Reliable Quality

Agile, Small-Batch Production

Accurate Delivery

Continuous Innovation for Customers

Building a High-Efficiency Production Line

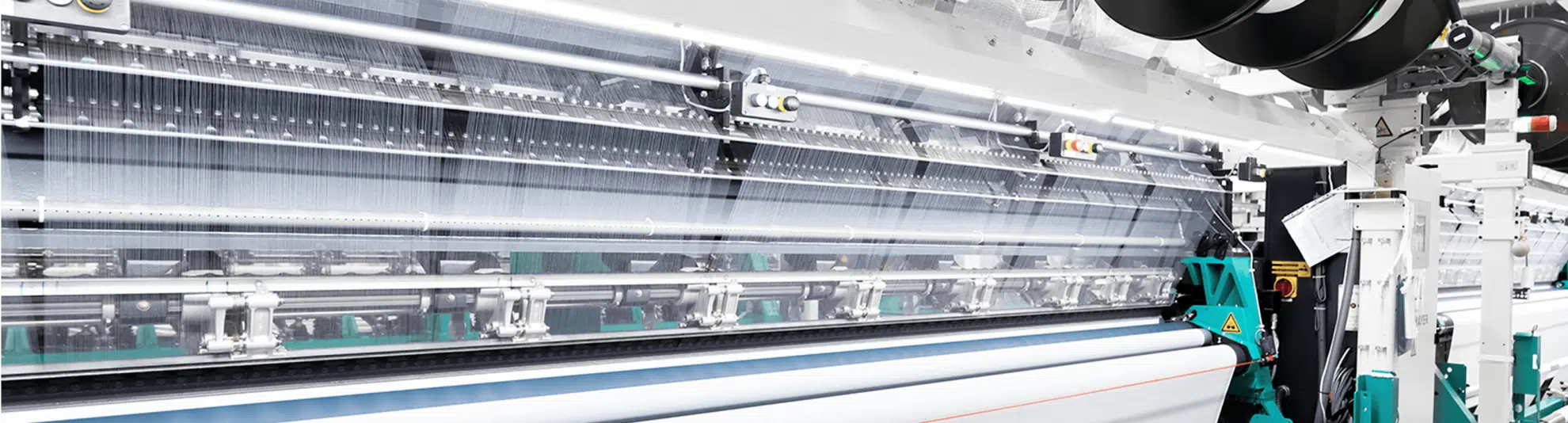

Precision Equipment from Germany and Japan

Tex Tile has invested in advanced textile machinery from Germany, Japan, and Italy, combining these with our proprietary textile processes to build a highly efficient production line. Backed by patented dyeing technology and an in-house laboratory, we have developed a fully integrated knitting, dyeing, and quality control system with exceptional precision and performance.

We are capable of handling both large-scale production and small customized fabric orders. Through a flexible and responsive manufacturing process, we ensure consistent fabric quality, physical performance, color fastness, and color accuracy. With ongoing research and innovation, we continue to deliver high-quality functional fabrics to a broad range of customers in the global market.

Green Manufacturing

Workplace Safety

Fabric dyeing typically involves a significant amount of chemical auxiliaries. At Tex Tile's dyeing house, Cotex, we have made major improvements to reduce the strong odor of acetic acid released during dyeing and have effectively eliminated PM2.0 dye particles — reflecting our commitment to workplace safety and environmental protection.

From the early planning stage of the production line, Cotex implemented a comprehensive industrial wastewater treatment system. The discharged water maintains a COD value below 100, lower than the government's standard of 140. Cotex was also the first dyeing house in Taiwan to adopt natural gas as its primary energy source, helping reduce carbon emissions and realize a sustainable, eco-friendly dyeing process.

Environmental Protection, Carbon Reduction, and Social Responsibility

Sustainable Governance, Green Commitment

Since its founding, Tex Tile has been dedicated to environmental protection and social responsibility, embedding ESG principles into every decision and facility plan. From the very beginning of plant construction, we integrated comprehensive systems for rainwater collection, cooling water recycling, and heat recovery — significantly reducing water and energy consumption.

In addition, by replacing traditional heavy oil with natural gas for heating, we have greatly lowered carbon emissions, achieving a green and environmentally responsible production model.

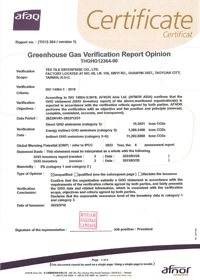

Carbon inventory and footprint

Tex Tile has actively pursued ISO 14067 certification for nylon-spandex and polyester-spandex fabrics in 2015 and 2024, and completed ISO 14064-1 carbon inventory in 2023, gaining deeper insights into energy use throughout the production process.

Continuously advancing toward net-zero goals

Tex Tile conducted greenhouse gas carbon inventory in 2023 and achieved ISO 14064-1 certification. Moving forward, we will continue advancing toward our net-zero goals by seeking alternative energy sources for high-emission areas and improving production efficiency to reduce energy consumption.

Committed to creating shared value with society

Upholding the spirit of giving back to society, Tex Tile transforms fabric scraps—once destined for incineration—into valuable handcrafted items through community workshops led by professional instructors. The program provides free materials, tools, space, lunch, and parking to encourage public participation, reduce environmental impact, and promote a sustainable fashion lifestyle. Additionally, fabric donations to the Taiwan Center in Turkey help create job opportunities for refugee women, fulfilling both social and environmental responsibilities.