Striving to build a sustainable ecosystem

E.Environmental

Pioneering sustainable textiles, leading the path to net zero.

Implement Water Recycling

Water recovery system

To realize its core goal of environmental protection, Tex Tile's dyeing facility, Cotex, has implemented an advanced wastewater treatment system in its dyeing and finishing processes. Utilizing a two-stage treatment with biological and sedimentation tanks, the system minimizes sludge output while ensuring water purity and ecological sustainability.

In addition, Cotex purchases steam generated from cogeneration by Ta-Yuan Cogen Co. to reduce carbon emissions. Heat steam and cooling water from the dyeing process are also recovered and treated as clean water, then recirculated into production. This significantly reduces water consumption and establishes a continuous loop of water recycling—effectively achieving true water resource regeneration.

Solar Power System Installation

Contributing to Taiwan's Green Energy Generation

From the initial construction of its Guanyin plant, Tex Tile integrated a rooftop solar power system into its design. As Taiwan is prone to earthquakes, nuclear power presents higher risks. In pursuit of a nuclear-free homeland and net-zero carbon emissions, green electricity has become a critical energy source.

Tex Tile and Cotex installed a 348-kilowatt solar system, generating an average of 380,000 kWh annually—actively contributing to the growth of Taiwan’s renewable energy capacity.

Carbon inventory and footprint

Continuously advancing toward net-zero goals

Tex Tile has actively pursued ISO 14067 certification for nylon-spandex and polyester-spandex fabrics in 2015 and 2024, and completed ISO 14064-1 carbon inventory in 2023, gaining deeper insights into energy use throughout the production process. Moving forward, we will continue advancing toward our net-zero goals by seeking alternative energy sources for high-emission areas and improving production efficiency to reduce energy consumption.

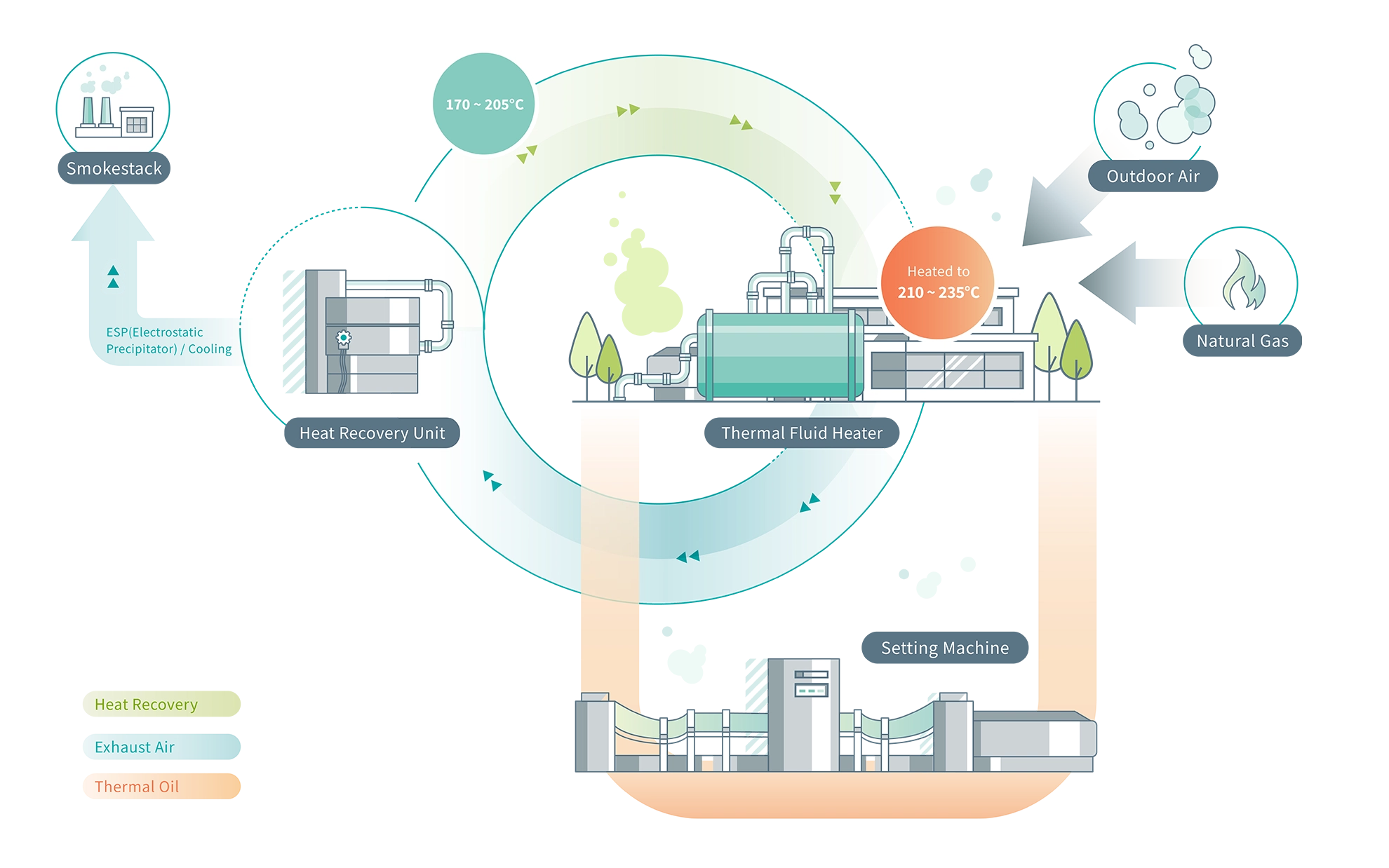

Thermal Energy Recovery System

Replacing fuel oil with natural gas

Cotex took the lead in replacing fuel oil with natural gas as the main fuel for dyeing and finishing, significantly reducing sulfur compound and suspended particulate emissions. Through a thermal recovery system, 170°C hot air is captured and reused. Compared to the traditional method of heating from room temperature to 210°C–235°C, this significantly reduces energy consumption and carbon emissions.

Rainwater Recycle

Sustainable & Green-Covered Facility

Tex Tile is committed to environmental protection, integrating ecological balance into facility planning. A rainwater recycle system has been installed to irrigate the factory’s green spaces. Over 20,000 plants have been cultivated, achieving a green coverage rate of 70% and significantly reducing the facility’s carbon footprint.

Greenery on the rooftop helps reduce heat transfer and absorb solar radiation. Tex Tile also pioneered the use of textile waste to partially replace soil in rooftop planting, reducing industrial waste while lightening the load on green structures. This approach demonstrates a circular use of resources and a commitment to environmental sustainability—reinforcing the company's dedication to a greener future.

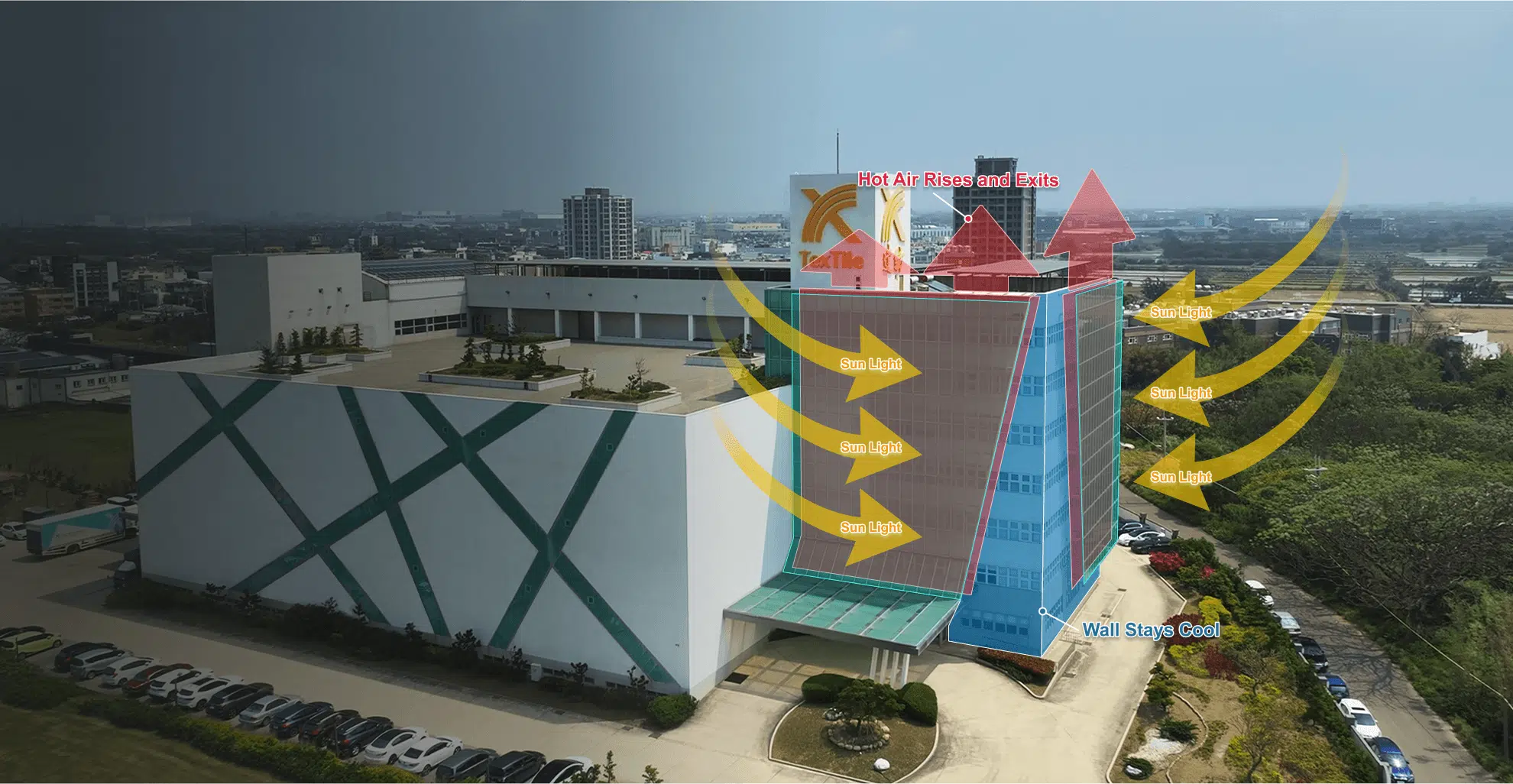

Architectural Cooling Facade

Reducing Air Conditioning Use for Energy and Carbon Reduction

The factory buildings are designed with a green glass facade that acts as a protective shell, shielding the walls from direct sunlight. When sunlight hits the glass, it generates hot air. This air rises through the gap between the building and the facade due to the chimney effect, where lighter hot air naturally rises. This passive ventilation prevents the building's walls from heating up, thereby reducing the need for air conditioning.

As a textile company, we designed the facade to resemble a jacket. Situated near the coast, the sea breeze lifts the "hem" of this architectural garment, creating a welcoming pathway that greets visitors like an open coat.

Committed to Social Inclusion & Shared Prosperity

S.Social

Textile Transformation for Waste Reduction — Building a Sustainable Society

Supporting Local Vulnerable Communities

Sustainable Living through Upcycled Textile Waste

Tex Tile offers free local handicraft classes using leftover textile materials as the main resource. Professional crochet instructors lead the sessions, inviting vulnerable groups from Taiwan's local communities to participate. All costs—including instructors, venue, materials, and meals—are fully covered, giving waste fabric a new life and promoting the concept of sustainable living.

Co-Creating the Future of Sports

Supporting Athletic Talent in Action

Tex Tile regularly sponsors professional performance sportswear for Taiwanese athletes, providing support and assistance as they showcase their skills on the international stage. We stand behind Taiwan's athletes in their pursuit of national pride and excellence.

Cultivating Integrity and Steady Management

G.Governance

Integrity-Driven Governance. Ensuring Equity and Justice

Ensuring Excellence in Quality

Digitalized Risk and Quality Management

Tex Tile leverages digital systems to strengthen supply chain management and has obtained ISO 9001 quality management certification. Through systematic process monitoring and continuous improvement, we effectively reduce production costs and risks, enhance operational efficiency, and ensure the exceptional quality of every product.

ISO 45001

Occupational Safety Certification & Employee Wellbeing

Tex Tile has established a comprehensive occupational safety system aligned with ISO 45001 standards. In our dyeing and finishing facilities, we have implemented automated control equipment for acid handling, significantly reducing employee exposure and minimizing acidic odors in the workplace. These measures ensure a healthier and safer environment for all staff.

In addition, Tex Tile is deeply committed to employee wellbeing, offering thorough health check-ups, parental support programs, and gender-friendly workplace policies—demonstrating our dedication to both safety and care.

SDGs

Together for a Sustainable Future

At Tex Tile, we build on environmental protection, embrace social responsibility, and uphold excellence in governance. These core principles reflect our firm commitment to the global circular economy. We are driving the green transformation of the textile industry and creating lasting value through sustainable innovation.